Products

HomeProductsWelding SolutionAccessoriesAbrasives & Wire BrushesPolishing & GrindingPFERD POLINOX Cross Buffs PNST

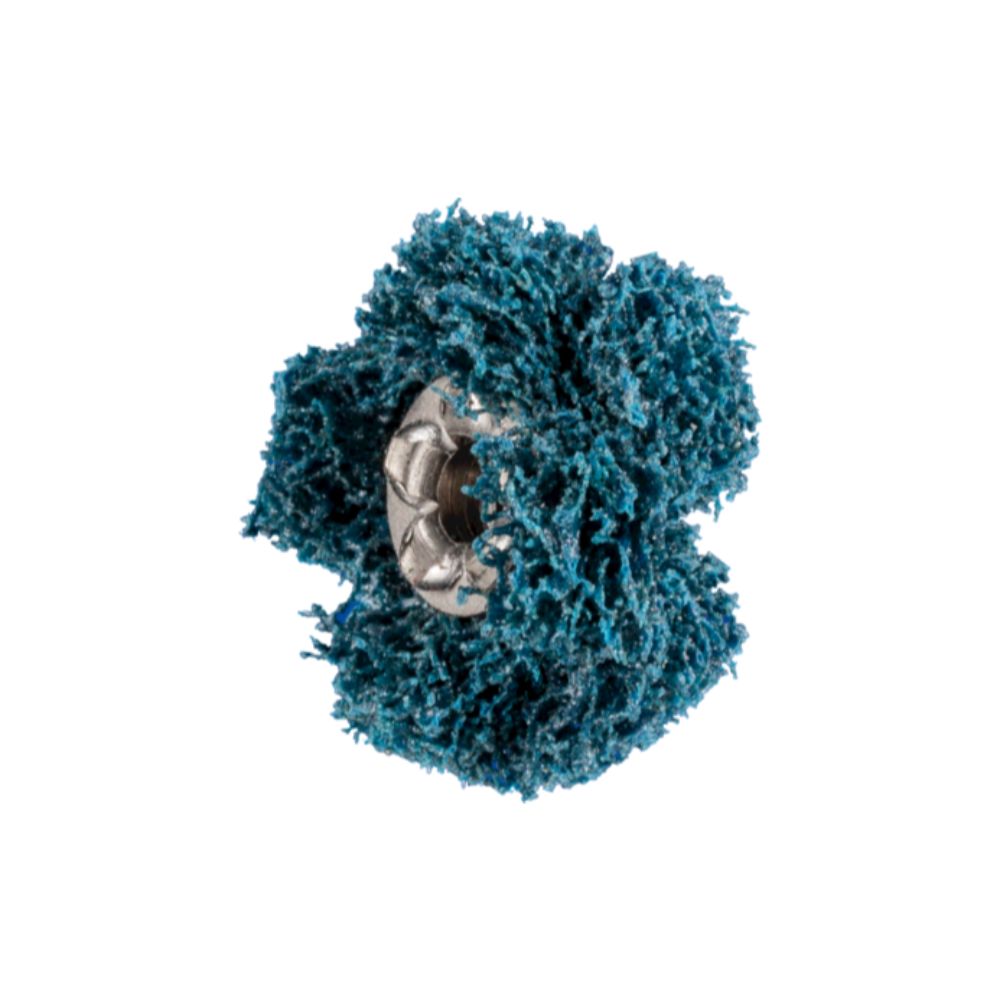

PFERD POLINOX Cross Buffs PNST

Suitable for cleaning, deburring and fine grinding of inner surfaces and contours.

Particularly suitable for hard-to-reach places such as drilled holes and indentations.

Please contact us for further inquiries including product variety, replacement parts and product details.

SKU: wsa0144

Category: Polishing & Grinding

Tags: Abrasives, cut off wheel, Files, flap discs, grinding dics, grinding wheel, mounted flap wheel, polishing and grinding tool, Wire Brushes

Description

Description

Suitable for cleaning, deburring and fine grinding of inner surfaces and contours.

Particularly suitable for hard-to-reach places such as drilled holes and indentations.

Materials that can be worked:

- Aluminium

- Cobalt-based alloys

- Other non-ferrous metals

- High-temperature-resistant materials

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Bronze

- Hard non-ferrous metal

- Titanium

- Titanium alloys

- Copper

- Soft non-ferrous metal

- Brass

- Zinc

- Stainless steel (INOX)

- Thermoplastics

- Fibre-reinforced duroplastics (GRP, CRP)

- Hardened, heat-treated steels over 1,200 N/mm2 (over 38 HRC)

- Steel materials with a hardness over 54 HRC

- Steel, cast steel

- Steels up to 1,200 N/mm² (< 38 HRC)

- Cast steel

Applications:

- Roughening

- Deburring

- Surface work

- Cleaning

- Structuring (matt finishing, brush matting and satin finishing)

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

Classification

| profi class 5.0 | AAA031c098 |

| eclass 8.1 | 21011318 |

| eclass 7.0 | 21011390 |

| eclass 4.1 | 21011313 |

Specifications

Technical information

| Opt. RPM from | 15000 RPM |

| Max. RPM | 25100 RPM |

| Dia. | 19 mm |

| No. of layers | 2 pcs. |

| Grit size | 100 |

| Packing unit | 20 pcs. |

| Material number | 44698192 |

Enquiry about PFERD POLINOX Cross Buffs PNST

Description

Description

Suitable for cleaning, deburring and fine grinding of inner surfaces and contours.

Particularly suitable for hard-to-reach places such as drilled holes and indentations.

Materials that can be worked:

- Aluminium

- Cobalt-based alloys

- Other non-ferrous metals

- High-temperature-resistant materials

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Bronze

- Hard non-ferrous metal

- Titanium

- Titanium alloys

- Copper

- Soft non-ferrous metal

- Brass

- Zinc

- Stainless steel (INOX)

- Thermoplastics

- Fibre-reinforced duroplastics (GRP, CRP)

- Hardened, heat-treated steels over 1,200 N/mm2 (over 38 HRC)

- Steel materials with a hardness over 54 HRC

- Steel, cast steel

- Steels up to 1,200 N/mm² (< 38 HRC)

- Cast steel

Applications:

- Roughening

- Deburring

- Surface work

- Cleaning

- Structuring (matt finishing, brush matting and satin finishing)

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

Classification

| profi class 5.0 | AAA031c098 |

| eclass 8.1 | 21011318 |

| eclass 7.0 | 21011390 |

| eclass 4.1 | 21011313 |

Specifications

Technical information

| Opt. RPM from | 15000 RPM |

| Max. RPM | 25100 RPM |

| Dia. | 19 mm |

| No. of layers | 2 pcs. |

| Grit size | 100 |

| Packing unit | 20 pcs. |

| Material number | 44698192 |