Products

PFRED COMBIDISC Abrasive Disc Diamond CD System

Exceptionally suitable for work on wear-resistant coatings and for hard facings made of tungsten carbide, chromium carbide, titanium carbide, etc. Particularly recommended for work on materials used for aircraft engine construction, e.g. Hastelloy, Inconel and titanium/titanium alloys. Also highly suitable for work on extremely hard materials such as tungsten carbide, glass, ceramics, enamel, stone and GRP/CRP.

Please contact us for further inquiries including product variety, replacement parts and product details.Description

Description

Exceptionally suitable for work on wear-resistant coatings and for hard facings made of tungsten carbide, chromium carbide, titanium carbide, etc. Particularly recommended for work on materials used for aircraft engine construction, e.g. Hastelloy, Inconel and titanium/titanium alloys. Also highly suitable for work on extremely hard materials such as tungsten carbide, glass, ceramics, enamel, stone and GRP/CRP.

Materials that can be worked:

- Cobalt-based alloys

- Other non-ferrous metals

- High-temperature-resistant materials

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Titanium

- Hard non-ferrous metal

- Titanium alloys

- Thermoplastics

- Fibre-reinforced duroplastics (GRP, CRP)

- Stone

Applications:

- Roughening

- Leveling

- Deburring

- Surface work

- Work on edges

- Sharpening

- Weld dressing

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

- Angle grinder

- Cordless angle grinder

Classification

| profi class 5.0 | AAA027c019 |

| eclass 8.1 | 21011318 |

| eclass 7.0 | 21011318 |

| eclass 4.1 | 21011304 |

Recommendations for use

- For the best results, use at a recommended cutting speed of 10–20 m/s.

- Use with hard or medium-hard COMBIDISC abrasive disc holders.

Specifications

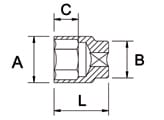

Technical information

| Opt. RPM from | 7500 RPM |

| Opt. RPM to | 15000 RPM |

| Outer dia. | 25 mm |

| Grit size | 251 |

| Packing unit | 10 pcs. |

| Material number | 42740001 |

Enquiry about PFRED COMBIDISC Abrasive Disc Diamond CD System

Description

Description

Exceptionally suitable for work on wear-resistant coatings and for hard facings made of tungsten carbide, chromium carbide, titanium carbide, etc. Particularly recommended for work on materials used for aircraft engine construction, e.g. Hastelloy, Inconel and titanium/titanium alloys. Also highly suitable for work on extremely hard materials such as tungsten carbide, glass, ceramics, enamel, stone and GRP/CRP.

Materials that can be worked:

- Cobalt-based alloys

- Other non-ferrous metals

- High-temperature-resistant materials

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Titanium

- Hard non-ferrous metal

- Titanium alloys

- Thermoplastics

- Fibre-reinforced duroplastics (GRP, CRP)

- Stone

Applications:

- Roughening

- Leveling

- Deburring

- Surface work

- Work on edges

- Sharpening

- Weld dressing

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

- Angle grinder

- Cordless angle grinder

Classification

| profi class 5.0 | AAA027c019 |

| eclass 8.1 | 21011318 |

| eclass 7.0 | 21011318 |

| eclass 4.1 | 21011304 |

Recommendations for use

- For the best results, use at a recommended cutting speed of 10–20 m/s.

- Use with hard or medium-hard COMBIDISC abrasive disc holders.

Specifications

Technical information

| Opt. RPM from | 7500 RPM |

| Opt. RPM to | 15000 RPM |

| Outer dia. | 25 mm |

| Grit size | 251 |

| Packing unit | 10 pcs. |

| Material number | 42740001 |