Products

HomeProductsWelding SolutionAccessoriesAbrasives & Wire BrushesPolishing & GrindingPFERD POLINOX Mounted Grinding Wheels PNZ Silicon carbide (SiC)

PFERD POLINOX Mounted Grinding Wheels PNZ Silicon carbide (SiC)

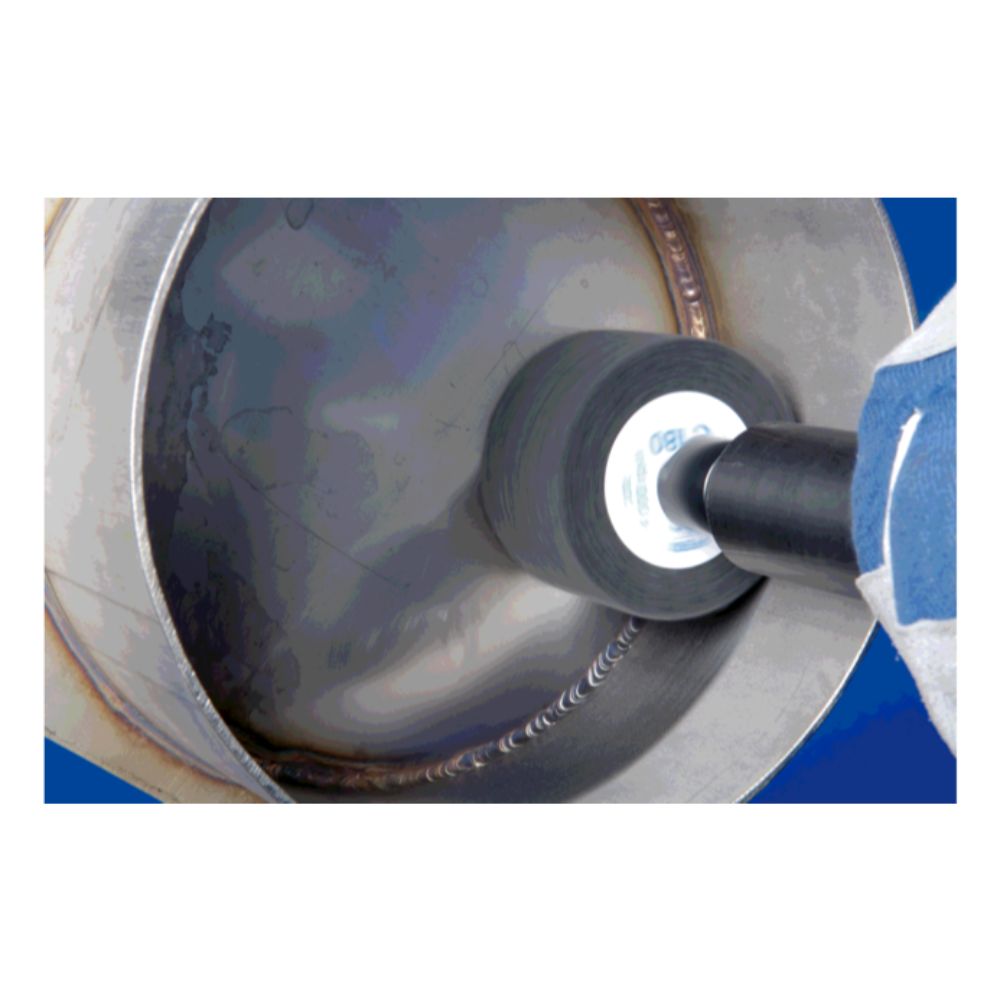

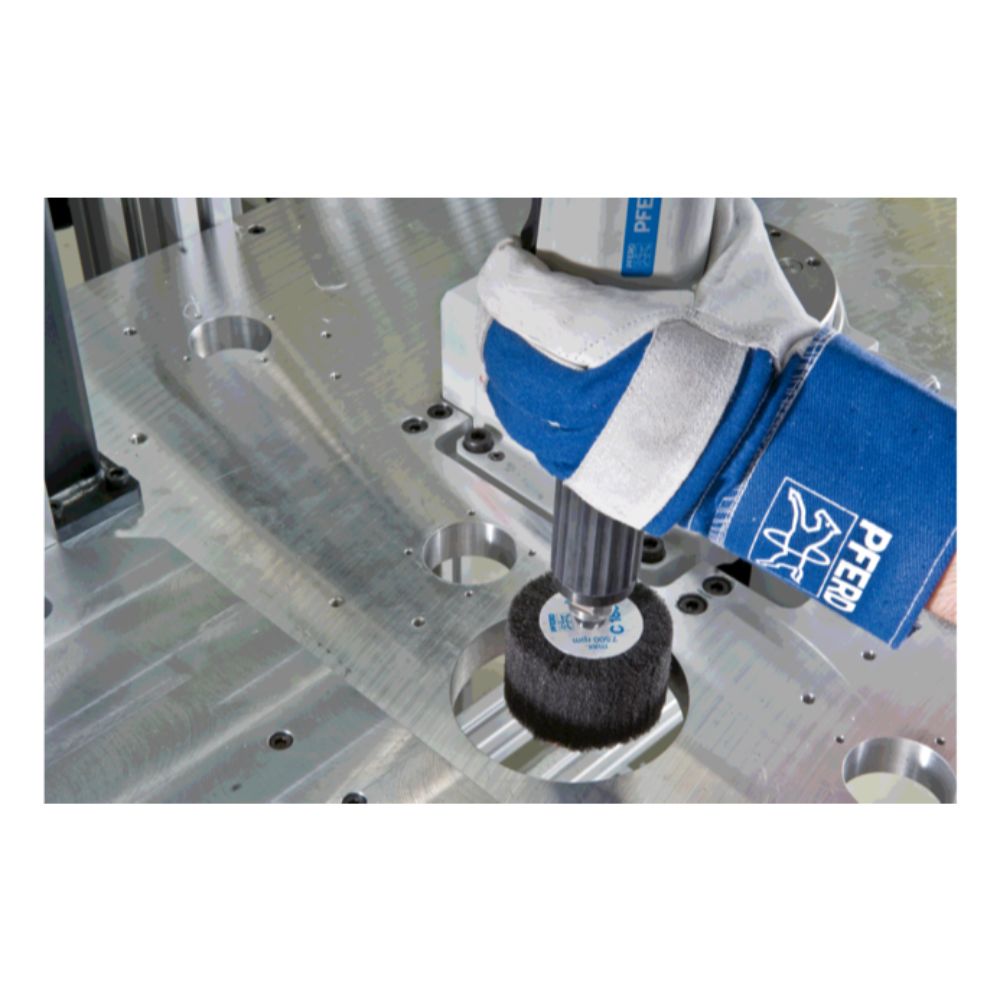

The non-woven abrasive material is arranged in multiple radial flaps, with abrasive cloth interlayers.

This flap structure facilitates improved stock removal and achieves a coarser surface finish.

Please contact us for further inquiries including product variety, replacement parts and product details.

SKU: wsa0132

Category: Polishing & Grinding

Tags: Abrasives, cut off wheel, Files, flap discs, grinding dics, grinding wheel, mounted flap wheel, polishing and grinding tool, Wire Brushes

Description

Description

The non-woven abrasive material is arranged in multiple radial flaps, with abrasive cloth interlayers.

This flap structure facilitates improved stock removal and achieves a coarser surface finish.

Materials that can be worked:

- Aluminium

- Cobalt-based alloys

- Other non-ferrous metals

- High-temperature-resistant materials

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Bronze

- Hard non-ferrous metal

- Titanium

- Titanium alloys

- Copper

- Soft non-ferrous metal

- Brass

- Zinc

- Stainless steel (INOX)

- Thermoplastics

- Fibre-reinforced duroplastics (GRP, CRP)

- Hardened, heat-treated steels over 1,200 N/mm2 (over 38 HRC)

- Steel materials with a hardness over 54 HRC

- Steel, cast steel

- Steels up to 1,200 N/mm² (< 38 HRC)

- Cast steel

Applications:

- Roughening

- Deburring

- Surface work

- Cleaning

- Structuring (matt finishing, brush matting and satin finishing)

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

Classification

| profi class 5.0 | AAA031c098 |

| eclass 8.1 | 21011318 |

| eclass 7.0 | 21011390 |

| eclass 4.1 | 21011305 |

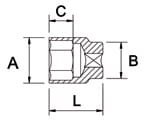

Specifications

Technical information

| Opt. RPM from | 4000 RPM |

| Max. RPM | 7500 RPM |

| Outer dia. | 80 mm |

| Width | 50 mm |

| Shank dia. | 6 mm |

| Shank length | 40 mm |

| Grit size | 100 |

| Packing unit | 10 pcs. |

| Material number | 44640806 |

Enquiry about PFERD POLINOX Mounted Grinding Wheels PNZ Silicon carbide (SiC)

Description

Description

The non-woven abrasive material is arranged in multiple radial flaps, with abrasive cloth interlayers.

This flap structure facilitates improved stock removal and achieves a coarser surface finish.

Materials that can be worked:

- Aluminium

- Cobalt-based alloys

- Other non-ferrous metals

- High-temperature-resistant materials

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Bronze

- Hard non-ferrous metal

- Titanium

- Titanium alloys

- Copper

- Soft non-ferrous metal

- Brass

- Zinc

- Stainless steel (INOX)

- Thermoplastics

- Fibre-reinforced duroplastics (GRP, CRP)

- Hardened, heat-treated steels over 1,200 N/mm2 (over 38 HRC)

- Steel materials with a hardness over 54 HRC

- Steel, cast steel

- Steels up to 1,200 N/mm² (< 38 HRC)

- Cast steel

Applications:

- Roughening

- Deburring

- Surface work

- Cleaning

- Structuring (matt finishing, brush matting and satin finishing)

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

Classification

| profi class 5.0 | AAA031c098 |

| eclass 8.1 | 21011318 |

| eclass 7.0 | 21011390 |

| eclass 4.1 | 21011305 |

Specifications

Technical information

| Opt. RPM from | 4000 RPM |

| Max. RPM | 7500 RPM |

| Outer dia. | 80 mm |

| Width | 50 mm |

| Shank dia. | 6 mm |

| Shank length | 40 mm |

| Grit size | 100 |

| Packing unit | 10 pcs. |

| Material number | 44640806 |