Products

Hypertherm Powermax 105 Tough Industrial Cutting and Gouging Duramax 75 Hand Torch

Designed for durability and reliability with SpringStart™ technology, Duramax® torches are available for handheld and machine cutting and gouging, and robotic cutting.

Duramax torches are available with an extensive array of specialty consumable options that perform a variety of applications such as gouging, fine feature cutting, extended reach cutting and cutting flush to base materials (flush cutting).

Please contact us for further inquiries including product variety, replacement parts and product details.Description

Benefits

For hand cutting and gouging jobs

Duramax® 75° and 15° hand torches are well suited for a variety of applications such as gouging, fine feature cutting, extended reach cutting, and flush cutting. The ergonomic design of the 75° torch is perfect for normal cutting, while the 15° torch directs heat away from the operator during heavy gouging and enables cutting overhead or in hard-to-reach areas.

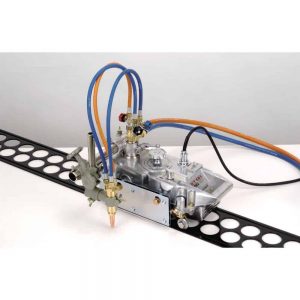

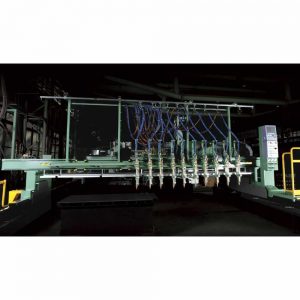

For machine jobs

Duramax full-length machine torches work with a wide variety of CNC cutting tables, track cutters, and pipe-cutters. Mini-machine torches are perfectly suited for lighter tables and pipe cutting situations where the full-length torch is too long.

For robotic jobs

The light weight, small size and built-in positioning features of Duramax robotic torches enable easy integration and operation with light robot arms. An optional clamp speeds integration.

Applications

Applications

- Drag cutting

For dragging the torch directly across the work piece - Extended reach cutting

For improved visibility & accessibility when cutting in confined spaces - Extended reach gouging

For improved visibility & accessibility when gouging in confined spaces - Fine feature cutting

For narrow kerf width with minimal dross and heat affected zone - Flush Cutting

For cutting closer to base materials using a 45 degree - Marking

For scoring, indicating part identification, hole or weld locations - Max Control Gouging

For precise metal removal, shallower gouge profiles and light metal washing - Max Removal Gouging

For aggressive metal removal, deep gouge profiles and extreme metal washing - Mechanized Cutting

For portable automation and table cutting - Precision Gouging

For spot and tack weld removal at very low output current (<25 A)

Enquiry about Hypertherm Powermax 105 Tough Industrial Cutting and Gouging Duramax 75 Hand Torch

Description

Benefits

For hand cutting and gouging jobs

Duramax® 75° and 15° hand torches are well suited for a variety of applications such as gouging, fine feature cutting, extended reach cutting, and flush cutting. The ergonomic design of the 75° torch is perfect for normal cutting, while the 15° torch directs heat away from the operator during heavy gouging and enables cutting overhead or in hard-to-reach areas.

For machine jobs

Duramax full-length machine torches work with a wide variety of CNC cutting tables, track cutters, and pipe-cutters. Mini-machine torches are perfectly suited for lighter tables and pipe cutting situations where the full-length torch is too long.

For robotic jobs

The light weight, small size and built-in positioning features of Duramax robotic torches enable easy integration and operation with light robot arms. An optional clamp speeds integration.

Applications

Applications

- Drag cutting

For dragging the torch directly across the work piece - Extended reach cutting

For improved visibility & accessibility when cutting in confined spaces - Extended reach gouging

For improved visibility & accessibility when gouging in confined spaces - Fine feature cutting

For narrow kerf width with minimal dross and heat affected zone - Flush Cutting

For cutting closer to base materials using a 45 degree - Marking

For scoring, indicating part identification, hole or weld locations - Max Control Gouging

For precise metal removal, shallower gouge profiles and light metal washing - Max Removal Gouging

For aggressive metal removal, deep gouge profiles and extreme metal washing - Mechanized Cutting

For portable automation and table cutting - Precision Gouging

For spot and tack weld removal at very low output current (<25 A)