Products

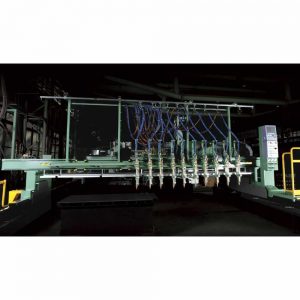

Hypertherm HyPerformance Plasma HPR-400XD

The HyPerformance® HPR400XD plasma system has been designed and built for maximum performance and productivity in x-y, bevel and robotic cutting operations. The versatile 400-amp rated system combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability, and delivers the ultimate in HyPerformance mild steel cutting, plus aluminum capability and unmatched stainless steel cut quality.

Description

The HyPerformance® HPR400XD plasma system has been designed and built for maximum performance and productivity in x-y, bevel and robotic cutting operations. The versatile 400-amp rated system combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability, and delivers the ultimate in HyPerformance mild steel cutting, plus aluminum capability and unmatched stainless steel cut quality.

Specification

| Mild steel cut capacity | Dross free Production pierce Maximum cutting capacity |

38 mm (1-1/2″)

50 mm (2″) 80 mm (3.2″) |

| Stainless steel cut capacity | Production pierce Maximum pierce** Severance |

45 mm (1-3/4″)

75 mm (3″) 80 mm (3.2″) |

| Aluminum cut capacity | Production pierce Severance |

45 mm (1-3/4″)

80 mm (3.2″) |

| Speed (Mild steel) |

Book specification at highest output current |

12 mm (1/2″)

4430 mm/m (170 ipm) |

| Cut angle | ISO 9013 range* |

2-4

|

| Weldability | Ready to weld | |

| Process gases by material (Plasma/shield) |

Mild steel

Stainless steel Aluminum |

02/Air, 02/02 H35/N2, N2/N2, H35-N2/N2, F5/N2 H35/N2, Air/Air, H35-N2/N2 |

| Process amps (Cutting) |

Not all processes available for all materials |

30-400 |

Enquiry about Hypertherm HyPerformance Plasma HPR-400XD

Description

The HyPerformance® HPR400XD plasma system has been designed and built for maximum performance and productivity in x-y, bevel and robotic cutting operations. The versatile 400-amp rated system combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability, and delivers the ultimate in HyPerformance mild steel cutting, plus aluminum capability and unmatched stainless steel cut quality.

Specification

| Mild steel cut capacity | Dross free Production pierce Maximum cutting capacity |

38 mm (1-1/2″)

50 mm (2″) 80 mm (3.2″) |

| Stainless steel cut capacity | Production pierce Maximum pierce** Severance |

45 mm (1-3/4″)

75 mm (3″) 80 mm (3.2″) |

| Aluminum cut capacity | Production pierce Severance |

45 mm (1-3/4″)

80 mm (3.2″) |

| Speed (Mild steel) |

Book specification at highest output current |

12 mm (1/2″)

4430 mm/m (170 ipm) |

| Cut angle | ISO 9013 range* |

2-4

|

| Weldability | Ready to weld | |

| Process gases by material (Plasma/shield) |

Mild steel

Stainless steel Aluminum |

02/Air, 02/02 H35/N2, N2/N2, H35-N2/N2, F5/N2 H35/N2, Air/Air, H35-N2/N2 |

| Process amps (Cutting) |

Not all processes available for all materials |

30-400 |