Products

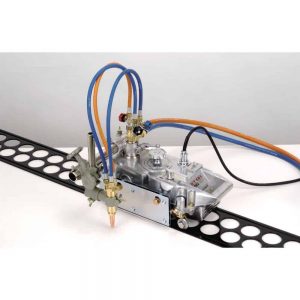

Synergic Automation SHQ Mini Manipulator

- Consists of raw material feeding frame, raw material auto feeding, roller auto conveyor, lifting and transferring roller, NC double shaft CNC flame/plasma cutting machine (including cutting elevating slewing roller and auto cutting cart), products auto output roller, products auto blanking roller, product blanking frame, GPK-630 type high speed beveling machine, hydraulic control part and electric control part.

- The pipe auto combination machine includes 1T adjustable positioner, cantilever welding machine, elevating support frame and electric control part for each machine

Description

- Consists of raw material feeding frame, raw material auto feeding, roller auto conveyor, lifting and transferring roller, NC double shaft CNC flame/plasma cutting machine (including cutting elevating slewing roller and auto cutting cart), products auto output roller, products auto blanking roller, product blanking frame, GPK-630 type high speed beveling machine, hydraulic control part and electric control part.

- The pipe auto combination machine includes 1T adjustable positioner, cantilever welding machine, elevating support frame and electric control part for each machine

Enquiry about Synergic Automation SHQ Mini Manipulator

Description

- Consists of raw material feeding frame, raw material auto feeding, roller auto conveyor, lifting and transferring roller, NC double shaft CNC flame/plasma cutting machine (including cutting elevating slewing roller and auto cutting cart), products auto output roller, products auto blanking roller, product blanking frame, GPK-630 type high speed beveling machine, hydraulic control part and electric control part.

- The pipe auto combination machine includes 1T adjustable positioner, cantilever welding machine, elevating support frame and electric control part for each machine