Products

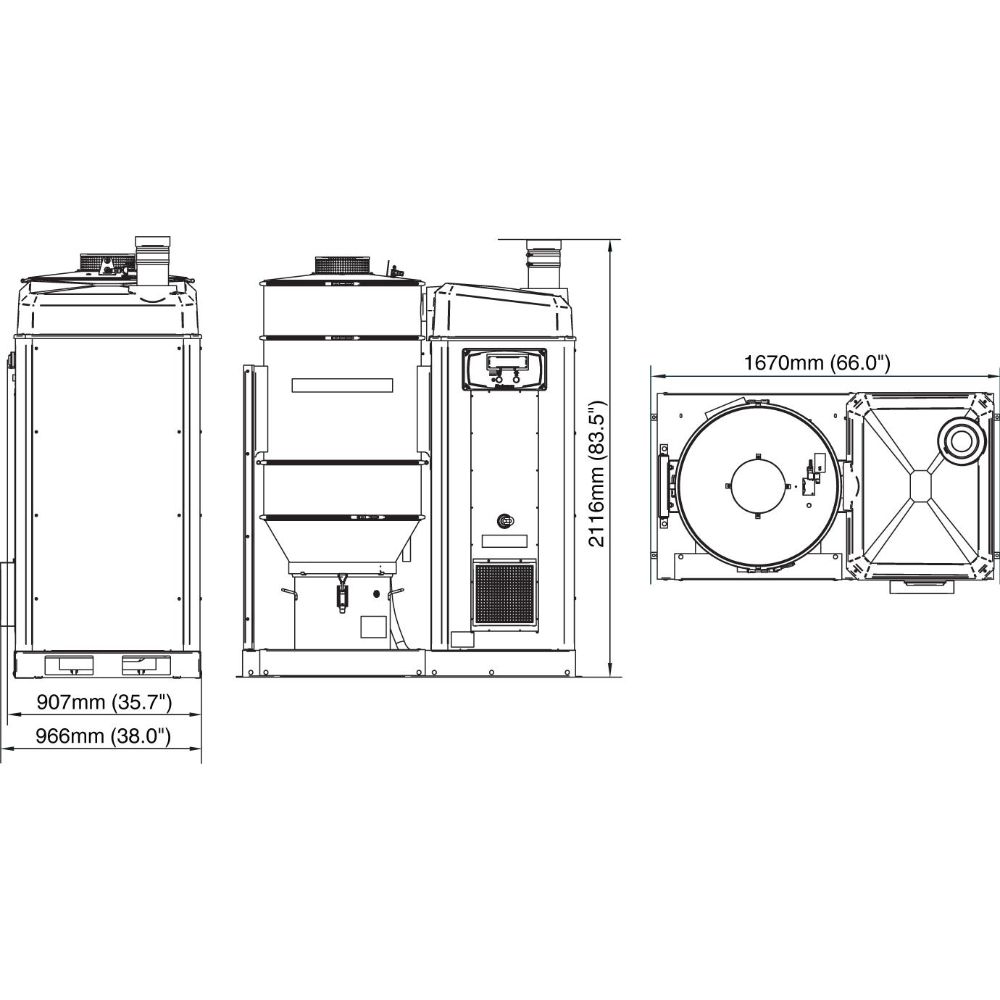

Nederman FlexPAK 800 High Vacuum

- Easy to install

- Built in PLC functions

- Low running and maintenance costs

- Built in safety functions

- Suitable for a wide range of applications

Description

The FlexPAK high vacuum unit represents the foremost solution on the market. The unit is designed for the extraction of welding fumes, grinding dust, metal chips etc. FlexPAK is suitable for cleaning the workplace, the shop floor, and machines. FlexPAK regulates the speed of the motor automatically depending on the vacuum demand. Compared to traditional controllers, FlexPAK provides an optimal, and well-balanced vacuum according to the need, ensuring energy-saving operation. The filters are effectively cleaned by applying powerful air bursts to the filter through quick opening valves. The dust is knocked off by the impact and collected in the dust bin. The sequence is controlled by the PLC, and it can be adjusted to suit every installation. This maximizes the life of the filter and ensures the correct functioning of the unit. FlexPAK can be fitted with different types of alarms, for example, level monitors for waste containers, filter indicators (for clogged filters) and fire alarms. Alarms can be activated at A and B levels and can be set to give both visual and audible signals. FlexPAK800 is a high vacuum unit, suitable for applications where metal chips, shot blasting grit and other heavy material need to be removed. FlexPAK1000 operates at a lower vacuum level and is suitable for extracting welding fumes and grinding dust and for use where a constant airflow, independent of the number of users, is a requirement.

Loading...

Loading...

Specifications

| Application | Dust, Granulate, Grit, Fumes, Swarf |

| Certifications | CE |

| Compressed air requirement | Dry and clean (Ø6 connection) |

| Dustbin volume (l) | 70 |

| Filter Area (m²) | 6 |

| Filter cleaning method | Reverse air pulse |

| Installation | Indoor, Outdoor |

| Max Airflow (m3/h) | 800 @ -20 kPa |

| Noise level (dB(A)) | 70 |

| Working pressure (kPa) | 20 |

Enquiry about Nederman FlexPAK 800 High Vacuum

Description

The FlexPAK high vacuum unit represents the foremost solution on the market. The unit is designed for the extraction of welding fumes, grinding dust, metal chips etc. FlexPAK is suitable for cleaning the workplace, the shop floor, and machines. FlexPAK regulates the speed of the motor automatically depending on the vacuum demand. Compared to traditional controllers, FlexPAK provides an optimal, and well-balanced vacuum according to the need, ensuring energy-saving operation. The filters are effectively cleaned by applying powerful air bursts to the filter through quick opening valves. The dust is knocked off by the impact and collected in the dust bin. The sequence is controlled by the PLC, and it can be adjusted to suit every installation. This maximizes the life of the filter and ensures the correct functioning of the unit. FlexPAK can be fitted with different types of alarms, for example, level monitors for waste containers, filter indicators (for clogged filters) and fire alarms. Alarms can be activated at A and B levels and can be set to give both visual and audible signals. FlexPAK800 is a high vacuum unit, suitable for applications where metal chips, shot blasting grit and other heavy material need to be removed. FlexPAK1000 operates at a lower vacuum level and is suitable for extracting welding fumes and grinding dust and for use where a constant airflow, independent of the number of users, is a requirement.

Loading...

Loading...

Specifications

| Application | Dust, Granulate, Grit, Fumes, Swarf |

| Certifications | CE |

| Compressed air requirement | Dry and clean (Ø6 connection) |

| Dustbin volume (l) | 70 |

| Filter Area (m²) | 6 |

| Filter cleaning method | Reverse air pulse |

| Installation | Indoor, Outdoor |

| Max Airflow (m3/h) | 800 @ -20 kPa |

| Noise level (dB(A)) | 70 |

| Working pressure (kPa) | 20 |