Products

OTC Daihen FD-V8 Arc Welding Robot

OTC Daihen FD-V8 Arc Welding Robot is mainly used for Arc & TIG welding, air plasma cutting and material-handling applications, it is built with reliability and efficiency.

Please contact us for further inquiries including product variety, replacement parts and product details.

SKU: 100032

Categories: Arc Welding, Handling Robot

Tags: OTC Daihen, OTC Daihen FD-V8, OTC Robotic, Welding Robot

Description

OTC Daihen FD-V8 Arc Welding Robot is mainly used for Arc & TIG welding, air plasma cutting and material-handling applications, it is built with reliability and efficiency.

ROBOT MANIPULATOR

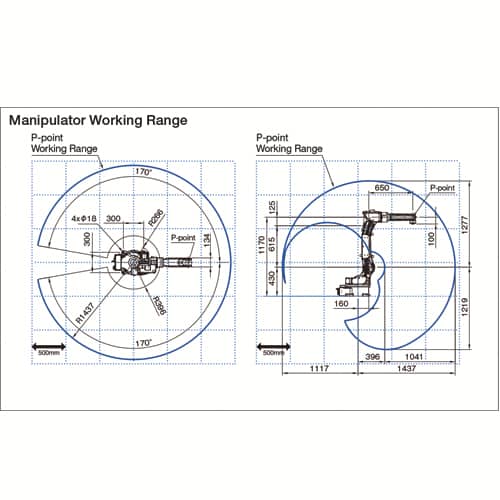

- Offers a wide working range with an independently articulated arm

- Seamless digital connection with all OTC DAIHEN brand welding power supplies

- Improved vibration restraining control provides smooth robot movement

- Built-in mechanical shock sensor for arc-welding

- Single source technology – all components are manufactured by OTC DAIHEN

- Highly versatile design supports many applications

FD11 ROBOT CONTROLLER

- Windows XP based open architecture

- Large memory capacity and 40 Input / 40 Output control signals

- Advanced PLC functions allow for ladder diagram editing directly through the teach pendant

- Network capabilities – connects to Ethernet, DeviceNet, and PROFIBUS connections (may require additional hardware)

TEACH PENDANT

- Icon displays assist in quick & easy teaching

- 640×480 VGA color screen with LED backlight 65536 color display

- 3 position enable switch provides increased safety

- Multi-screen function allows user to view up to 4 screens simultaneously

- On-screen help function with complete instruction manuals

- Standard touch screen display with jog dial operation

Specification

| Specification | Value |

|---|---|

| Number of Axes | 6 |

| Maximum Payload Capacity | 8 kg |

| Positional Repeatability | ± 0.08 mm |

| Drive Capacity | 3016 W |

| Working Range, Arm, J1 (Rotation) | ± 170° (±50°) |

| Working Range, Arm, J2 (Lower Arm) | – 155° to + 90° |

| Working Range, Arm, J3 (Upper Arm) | – 170° to + 190° |

| Working Range, Wrist, J4 (Swing) | ± 180° |

| Working Range, Wrist, J5 (Bending) | – 50° to + 230° |

| Working Range, Wrist, J6 (Twist) | ± 360° |

| Maximum Velocity, Arm, J1 (Rotation) | 4.19 rad/s (240°/s) (3.32 rad/s (190°/s) |

| Maximum Velocity, Arm, J2 (Lower Arm) | 4.19 rad/s (240°/s) |

| Maximum Velocity, Arm, J3 (Upper Arm) | 4.01 rad/s (230°/s) |

| Maximum Velocity, Wrist, J4 (Swing) | 7.50 rad/s (430°/s) |

| Maximum Velocity, Wrist, J5 (Bending) | 7.50 rad/s (430°/s) |

| Maximum Velocity, Wrist, J6 (Twist) | 11.00 rad/s (630°/s) |

| Wrist Load, Allowable Moment, J4 (Swing) | 17.6 N*m |

| Wrist Load, Allowable Moment, J5 (Bending) | 17.6 N*m |

| Wrist Load, Allowable Moment, J6 (Twist) | 7.8 N*m |

| Wrist Load, Allowable Moment of Inertia, J4 (Swing) | 0.43 kg*m² |

| Wrist Load, Allowable Moment of Inertia, J5 (Bending) | 0.43 kg*m² |

| Wrist Load, Allowable Moment of Inertia, J6 (Twist) | 0.09 kg*m² |

| Arm operation cross-sectional area | 3.11 m² x 340° |

| Ambient Conditions | 0~45°C, 20 ~ 80% RH (No condensation) |

| Mass | 140 kg |

| Upper arm payload capacity | 10 kg |

| Installation type | Floor / Ceiling / Wall |

| Paint color | White (Munsell notation 10GY 9/1) |

Catalogue

Loading...

Loading...

Enquiry about OTC Daihen FD-V8 Arc Welding Robot

Description

OTC Daihen FD-V8 Arc Welding Robot is mainly used for Arc & TIG welding, air plasma cutting and material-handling applications, it is built with reliability and efficiency.

ROBOT MANIPULATOR

- Offers a wide working range with an independently articulated arm

- Seamless digital connection with all OTC DAIHEN brand welding power supplies

- Improved vibration restraining control provides smooth robot movement

- Built-in mechanical shock sensor for arc-welding

- Single source technology – all components are manufactured by OTC DAIHEN

- Highly versatile design supports many applications

FD11 ROBOT CONTROLLER

- Windows XP based open architecture

- Large memory capacity and 40 Input / 40 Output control signals

- Advanced PLC functions allow for ladder diagram editing directly through the teach pendant

- Network capabilities – connects to Ethernet, DeviceNet, and PROFIBUS connections (may require additional hardware)

TEACH PENDANT

- Icon displays assist in quick & easy teaching

- 640×480 VGA color screen with LED backlight 65536 color display

- 3 position enable switch provides increased safety

- Multi-screen function allows user to view up to 4 screens simultaneously

- On-screen help function with complete instruction manuals

- Standard touch screen display with jog dial operation

Specification

| Specification | Value |

|---|---|

| Number of Axes | 6 |

| Maximum Payload Capacity | 8 kg |

| Positional Repeatability | ± 0.08 mm |

| Drive Capacity | 3016 W |

| Working Range, Arm, J1 (Rotation) | ± 170° (±50°) |

| Working Range, Arm, J2 (Lower Arm) | – 155° to + 90° |

| Working Range, Arm, J3 (Upper Arm) | – 170° to + 190° |

| Working Range, Wrist, J4 (Swing) | ± 180° |

| Working Range, Wrist, J5 (Bending) | – 50° to + 230° |

| Working Range, Wrist, J6 (Twist) | ± 360° |

| Maximum Velocity, Arm, J1 (Rotation) | 4.19 rad/s (240°/s) (3.32 rad/s (190°/s) |

| Maximum Velocity, Arm, J2 (Lower Arm) | 4.19 rad/s (240°/s) |

| Maximum Velocity, Arm, J3 (Upper Arm) | 4.01 rad/s (230°/s) |

| Maximum Velocity, Wrist, J4 (Swing) | 7.50 rad/s (430°/s) |

| Maximum Velocity, Wrist, J5 (Bending) | 7.50 rad/s (430°/s) |

| Maximum Velocity, Wrist, J6 (Twist) | 11.00 rad/s (630°/s) |

| Wrist Load, Allowable Moment, J4 (Swing) | 17.6 N*m |

| Wrist Load, Allowable Moment, J5 (Bending) | 17.6 N*m |

| Wrist Load, Allowable Moment, J6 (Twist) | 7.8 N*m |

| Wrist Load, Allowable Moment of Inertia, J4 (Swing) | 0.43 kg*m² |

| Wrist Load, Allowable Moment of Inertia, J5 (Bending) | 0.43 kg*m² |

| Wrist Load, Allowable Moment of Inertia, J6 (Twist) | 0.09 kg*m² |

| Arm operation cross-sectional area | 3.11 m² x 340° |

| Ambient Conditions | 0~45°C, 20 ~ 80% RH (No condensation) |

| Mass | 140 kg |

| Upper arm payload capacity | 10 kg |

| Installation type | Floor / Ceiling / Wall |

| Paint color | White (Munsell notation 10GY 9/1) |

Catalogue

Loading...

Loading...