Products

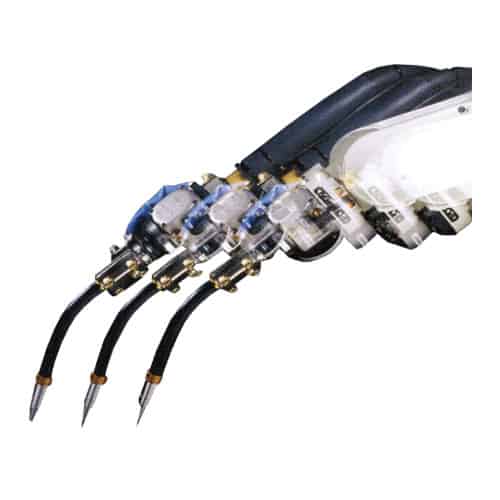

OTC Daihen Torch Sensor FD-WD

OTC Daihen Torch Sensor FD-WD – Workpiece position detection sensor by touching the welding wire.

Please contact us for further inquiries including product variety, replacement parts and product details.

SKU: 100038

Category: Robotics Accessories

Tags: OTC Arc Welding Machine, OTC Automation, OTC Daihen, OTC Daihen MIG Machine, OTC Daihen Robotic, OTC Daihen Welder, OTC DAIHEN Welding Machine, OTC Robotic

Description

OTC Daihen Torch Sensor FD-WD – Workpiece position detection sensor by touching the welding wire.

Features:

- Applicable to all the workpieces with a medium thickness or thicker.

- Most inexpensive among all workpiece position detection sensors.

- Requires no separate sensor unit because this sensor has a built-in controller.

- Allows high-speed search at up to 360 cm/min.

- A separate sensor unit (optional) is ready for hardly energized surfaces such as rust and black scale.

Specification

| Workpiece position detection | (The max two-way displacement detection rate per site is about 5 seconds) |

| Seam tracking | X |

| Recognition of groove shape | X |

| Combination with other sensors | This sensor can be used together with an arc sensor or TIG sensor |

| Applicable workpieces | Plate thickness: 3.2mm or more |

| Accuracy | ~ 1.0mm (provided that the bend of wire does not change) |

| Workpiece material | All the materials and surfaces to be energized |

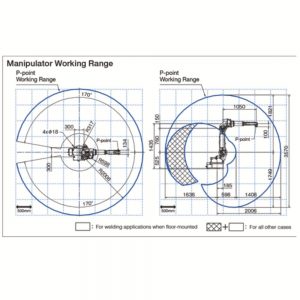

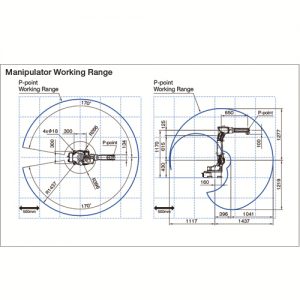

Catalogue

Loading...

Loading...

Enquiry about OTC Daihen Torch Sensor FD-WD

Description

OTC Daihen Torch Sensor FD-WD – Workpiece position detection sensor by touching the welding wire.

Features:

- Applicable to all the workpieces with a medium thickness or thicker.

- Most inexpensive among all workpiece position detection sensors.

- Requires no separate sensor unit because this sensor has a built-in controller.

- Allows high-speed search at up to 360 cm/min.

- A separate sensor unit (optional) is ready for hardly energized surfaces such as rust and black scale.

Specification

| Workpiece position detection | (The max two-way displacement detection rate per site is about 5 seconds) |

| Seam tracking | X |

| Recognition of groove shape | X |

| Combination with other sensors | This sensor can be used together with an arc sensor or TIG sensor |

| Applicable workpieces | Plate thickness: 3.2mm or more |

| Accuracy | ~ 1.0mm (provided that the bend of wire does not change) |

| Workpiece material | All the materials and surfaces to be energized |

Catalogue

Loading...

Loading...