Products

HomeProductsWelding SolutionAutomationRoboticsRobotics AccessoriesOTC Daihen External Axis Positioner 1PB1000

OTC Daihen External Axis Positioner 1PB1000

OTC Daihen Positioner Headstock – 1PB Series. This can be used to build varied jig systems with a large degree of positioning flexibility. A hole through the center of the rotary table, enabling cables and hoses to be routed through easily.

Please contact us for further inquiries including product variety, replacement parts and product details.

SKU: otc003

Category: Robotics Accessories

Tags: OTC Automation, OTC Daihen, OTC Daihen Robotic, OTC DAIHEN Welding Machine, OTC Robotic

Description

OTC Daihen External Axis Positioner 1PB1000

Features:

- The 5 sides of the housing are provided with tapped holes, which permit random mounting positions allowing various jig systems to be set up

- A hole through the center of the rotary table enables easy routing of cables and hoses

- A secondary terminal for welding (500A) is provided as standard built-in equipment

- Can be used as a single-axis, double support positioner in combination with the tailstock and stand (optional)

- Application signal cable and 4 air inlet ports can be fed through the center of the table (optional)

- Voltage detection wire and connection terminal to let the low spatter welding power supply DL350 to perform optimally are provided as standard

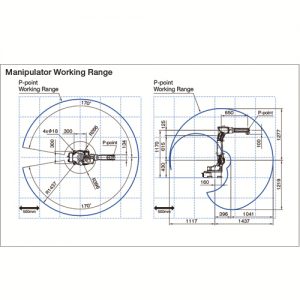

Specification

| Model Name | A2PB1002-E |

| Max. Payload Capacity | 1000 kg |

| Rotating Speed | 1.3 rad/s {72° /s} |

| Allowable Rotating Speed | 1078 N . M |

| Position Repeatability | ~0.1mm (Position at R300mm) |

| Stop Position | Random |

| Weight | 220 kg |

Catalogue

Loading...

Loading...

Enquiry about OTC Daihen External Axis Positioner 1PB1000

Description

OTC Daihen External Axis Positioner 1PB1000

Features:

- The 5 sides of the housing are provided with tapped holes, which permit random mounting positions allowing various jig systems to be set up

- A hole through the center of the rotary table enables easy routing of cables and hoses

- A secondary terminal for welding (500A) is provided as standard built-in equipment

- Can be used as a single-axis, double support positioner in combination with the tailstock and stand (optional)

- Application signal cable and 4 air inlet ports can be fed through the center of the table (optional)

- Voltage detection wire and connection terminal to let the low spatter welding power supply DL350 to perform optimally are provided as standard

Specification

| Model Name | A2PB1002-E |

| Max. Payload Capacity | 1000 kg |

| Rotating Speed | 1.3 rad/s {72° /s} |

| Allowable Rotating Speed | 1078 N . M |

| Position Repeatability | ~0.1mm (Position at R300mm) |

| Stop Position | Random |

| Weight | 220 kg |

Catalogue

Loading...

Loading...